I will not describe my process here, but my reference is a set of amazing videos by Dmitry Dementiev:

https://www.youtube.com/watch?v=hKJiR35kjpI

https://www.youtube.com/watch?v=El_O8IMgWUk

https://www.youtube.com/watch?v=yPS-ldzMQRI

It is all in Russian. There are similar English videos on youtube, but I followed Dimitry's since he describes things really well. If you don't understand Russian and still want to know how to do it - let me know, I will try to do some translation.

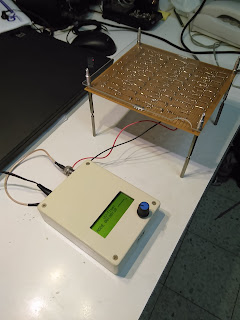

Anyway, here is my first home made PCB.

|

| UV-Timer PCB immediately after etching |

|

| UV-Timer PCB with photoresist removed |

It is a modified version of Dmitry's timer for UV LED lamp.

Here is my schematics:

There are few changes compared with Dmitry's schematic:

- I have put another MOSFET and controlling resistors

- I removed controlling buttons. All control is done from rotary encoder

- I have wrote the firmware from scratch. Just for fun.

All the code and schematics are at https://github.com/kloper/uv-timer

A few more photos of the timer being built:

|

| Board fully populated |

|

| Bottom side with a few patches for a first version (fixed on github) |

|

| Fully populated board |

|

| Very first working version of firmware |